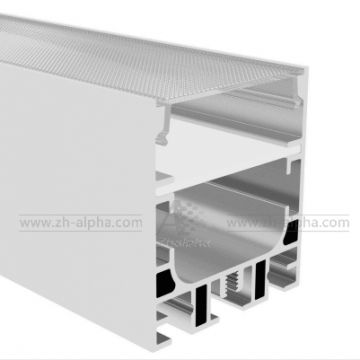

Plastic Extrusion Manufacturer Based in China

We are the First Chinese Solution Provider of Lighting Control

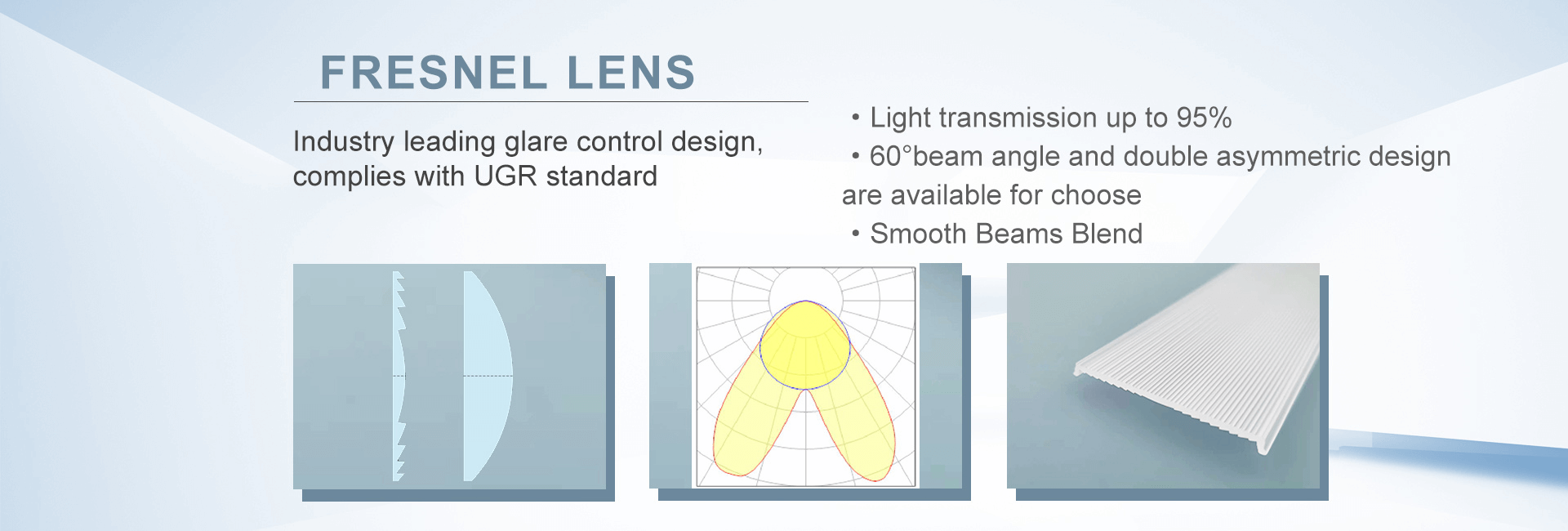

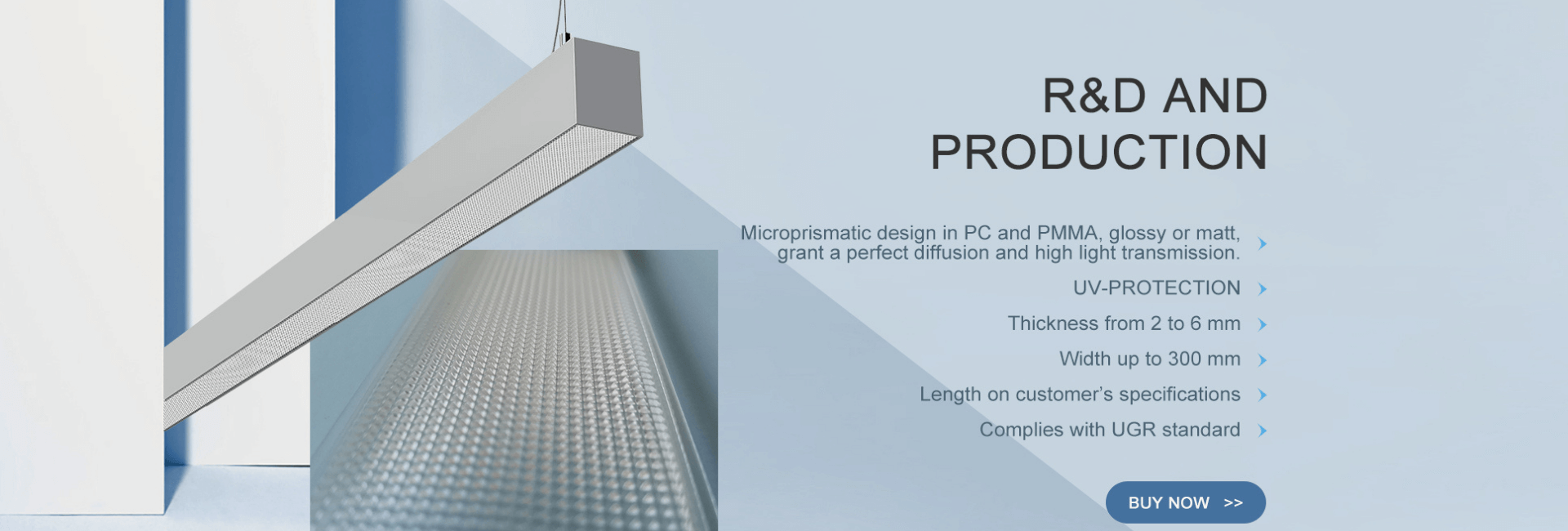

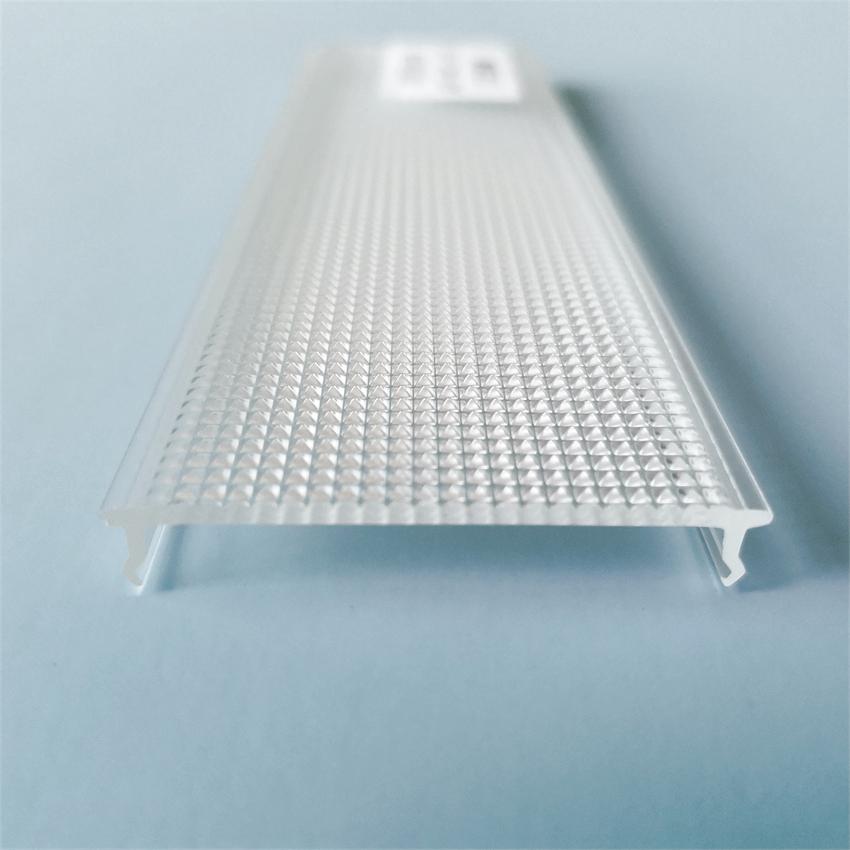

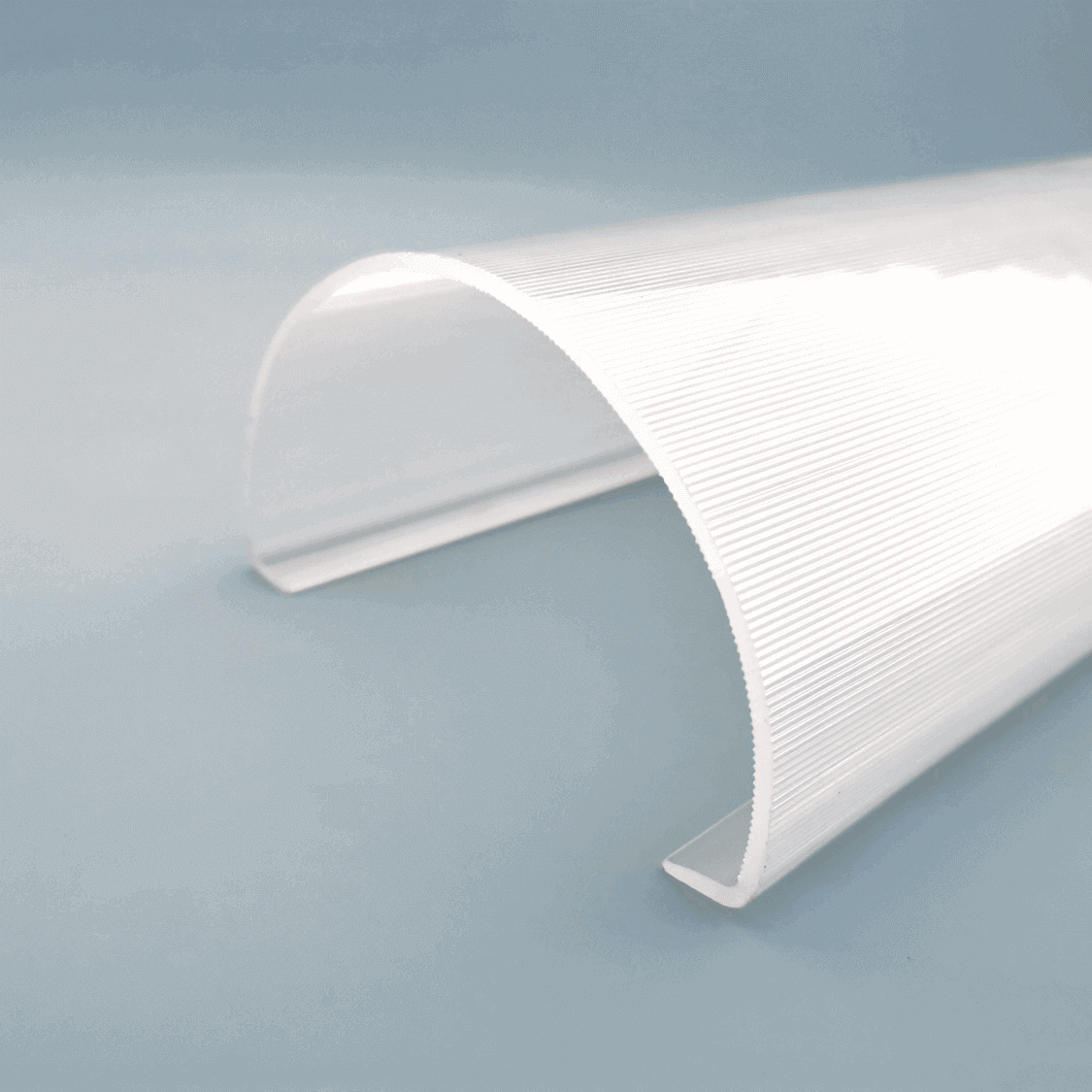

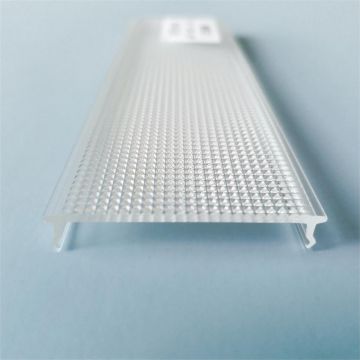

Alpha (Zhuhai) Optical Co., Ltd. is a premier manufacturer with R&D and production in one, specializing in precision and optical plastic extrusion, injection molding, and custom product processing. With 20+ years manufacturer in plastic extrusion and 10+ years experience in lighting, we guide lighting OEM manufacturers get optimal solution. Our expertise lies in our constant innovation, meticulous service, and prompt product delivery. At ALPHA, we take pride in supplying our clients with world-class and high-quality standard and custom-made light diffuser and optical lens.

简体中文

简体中文