Product Evaluation & Design

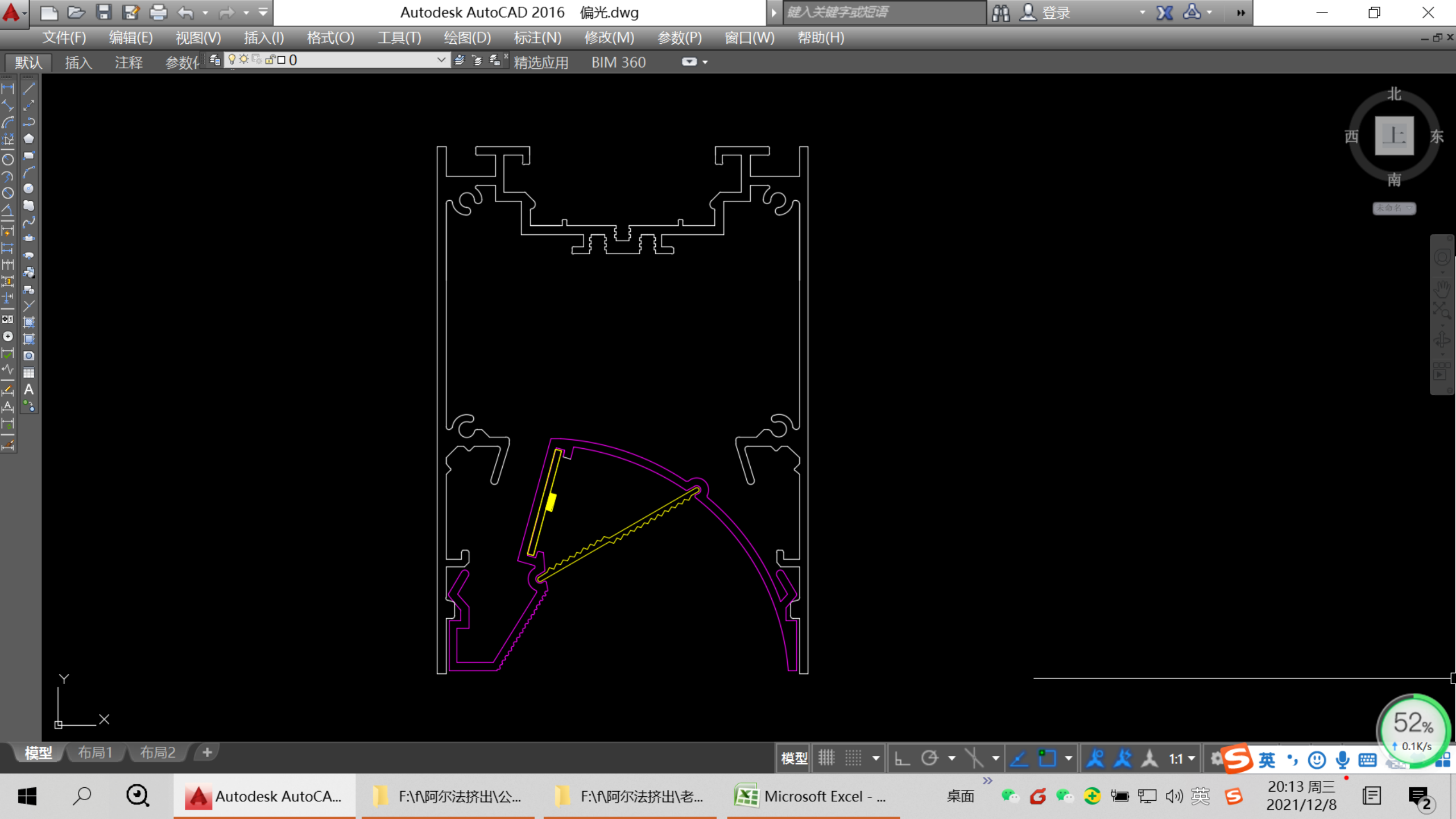

1. Get Drawing

Customer provide drawings or we help for drawings design according to your application.

2. Structural Simulation

Alpha will do fitment checking with CAD, Proe and Solidwork, to make sure the wanted structure is possible.

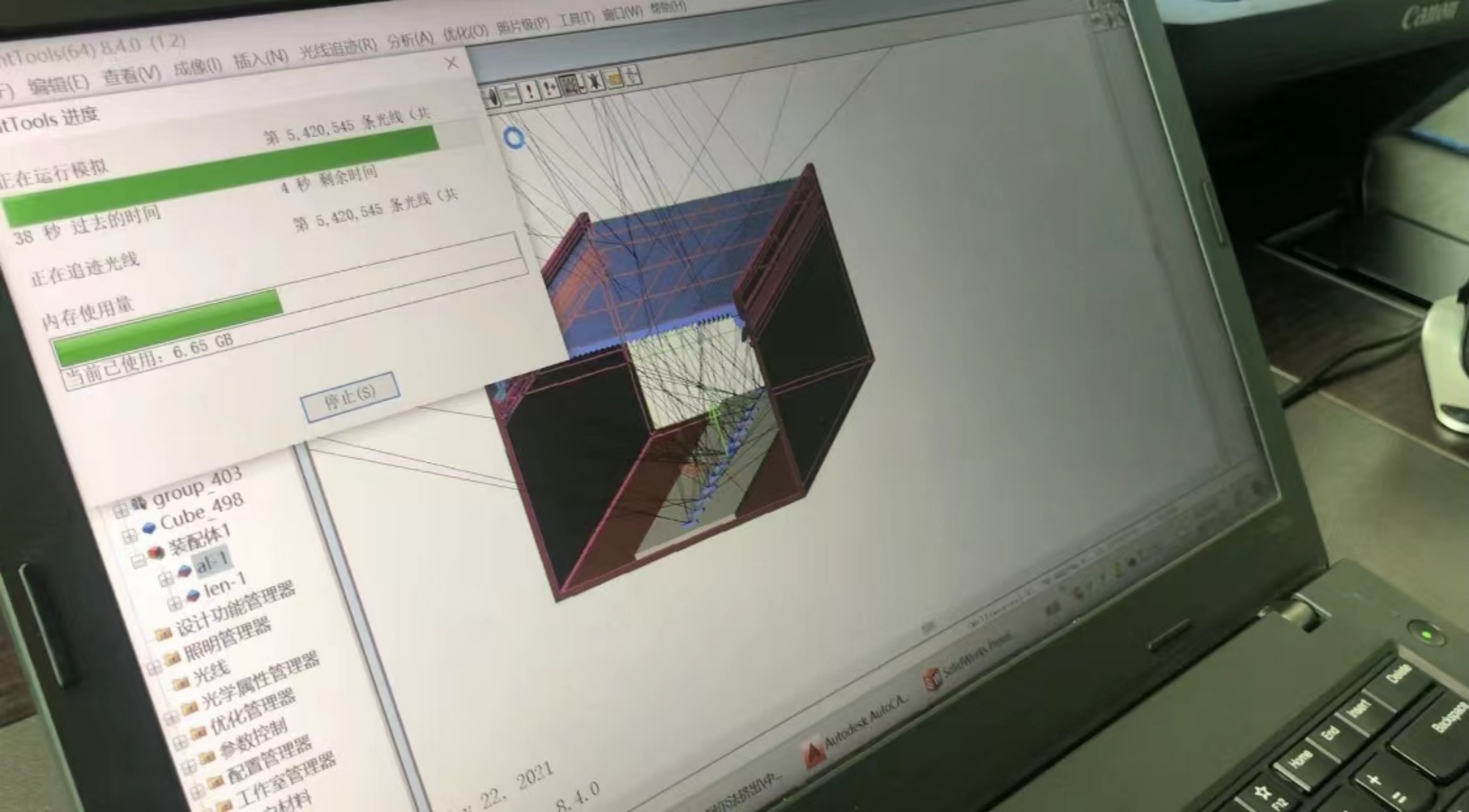

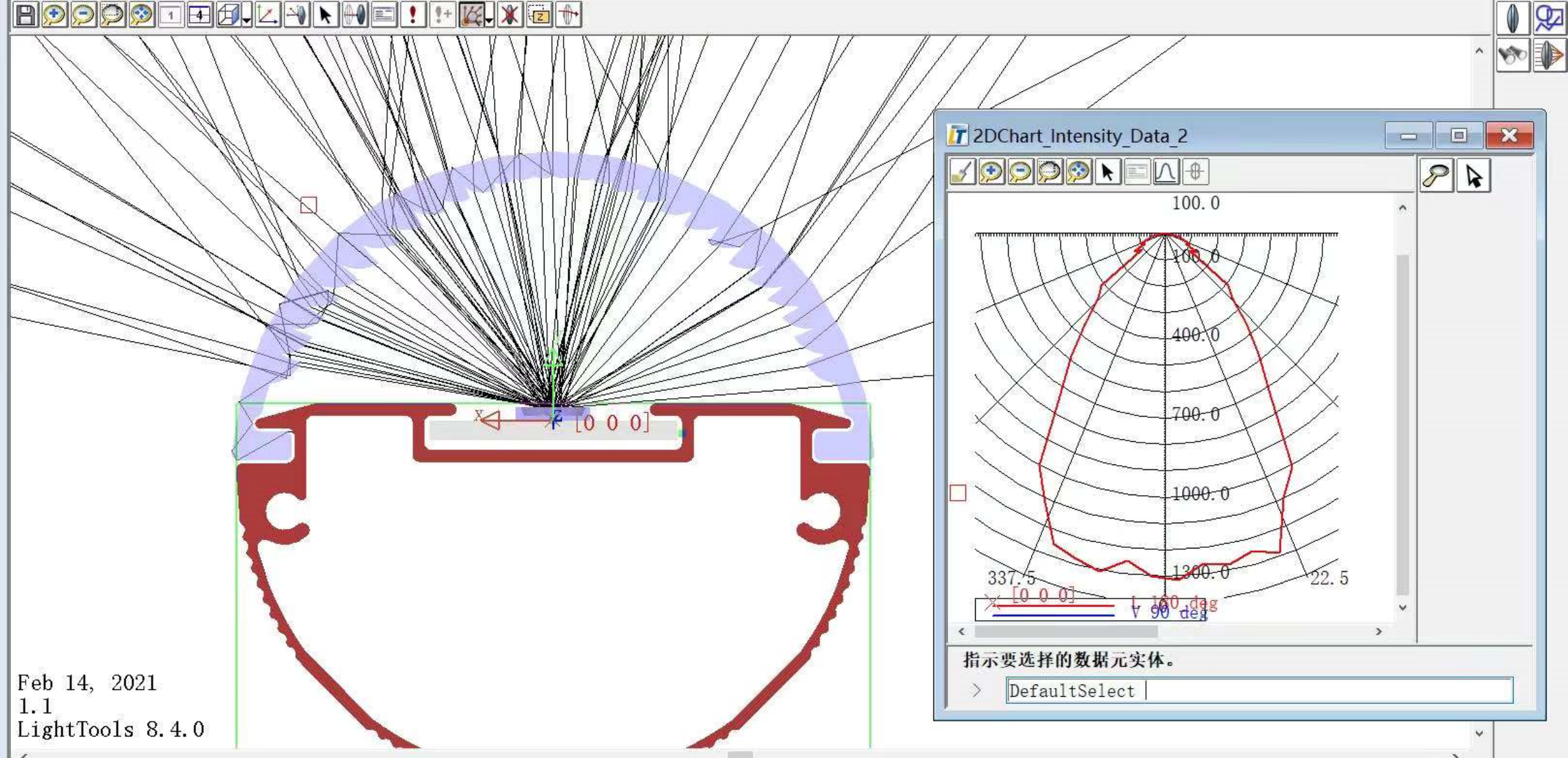

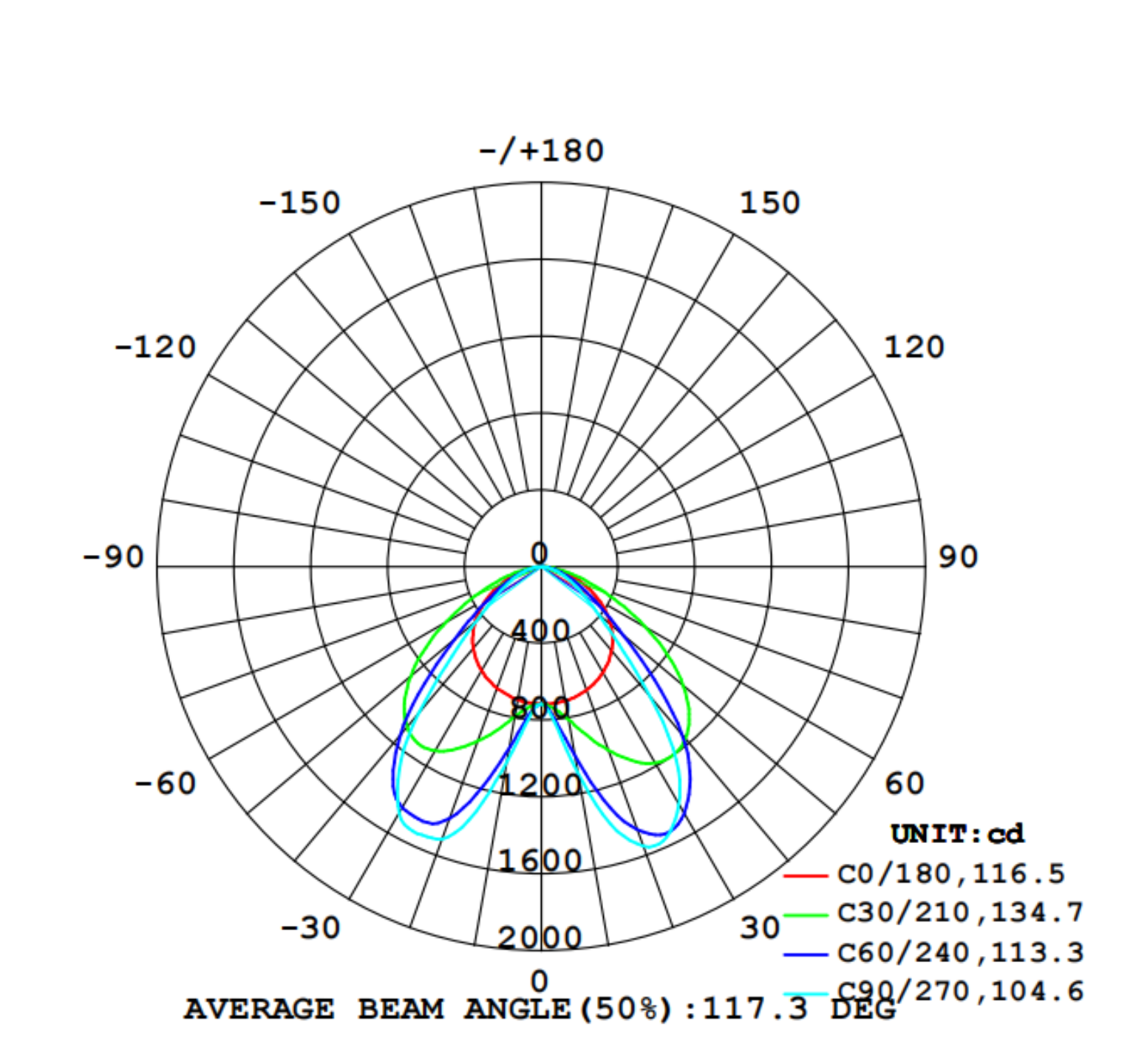

3. Optical Simulation

For Lighting application, Alpha will do optical simumatchlation with LightTool, DiaLux and Tracepro to make sure the beam angle is wanted.

4. Provide DFM

5. Place Order

Make offer including tooling cost and product unit price, then confirm the purchase order.

Tooling Process & Sample Approval

1. Design Mold Drawing(3 Days)

Experienced mold engineers design the mold according to the required shape and size

2. Raw Material Procurement & Processing(7 Days)

Purchasing raw material, as well as mold processing incluidng drilling, lathes, CNC, wiring cut, etc.

3. Trial production(3 Days)

Arrange trial production

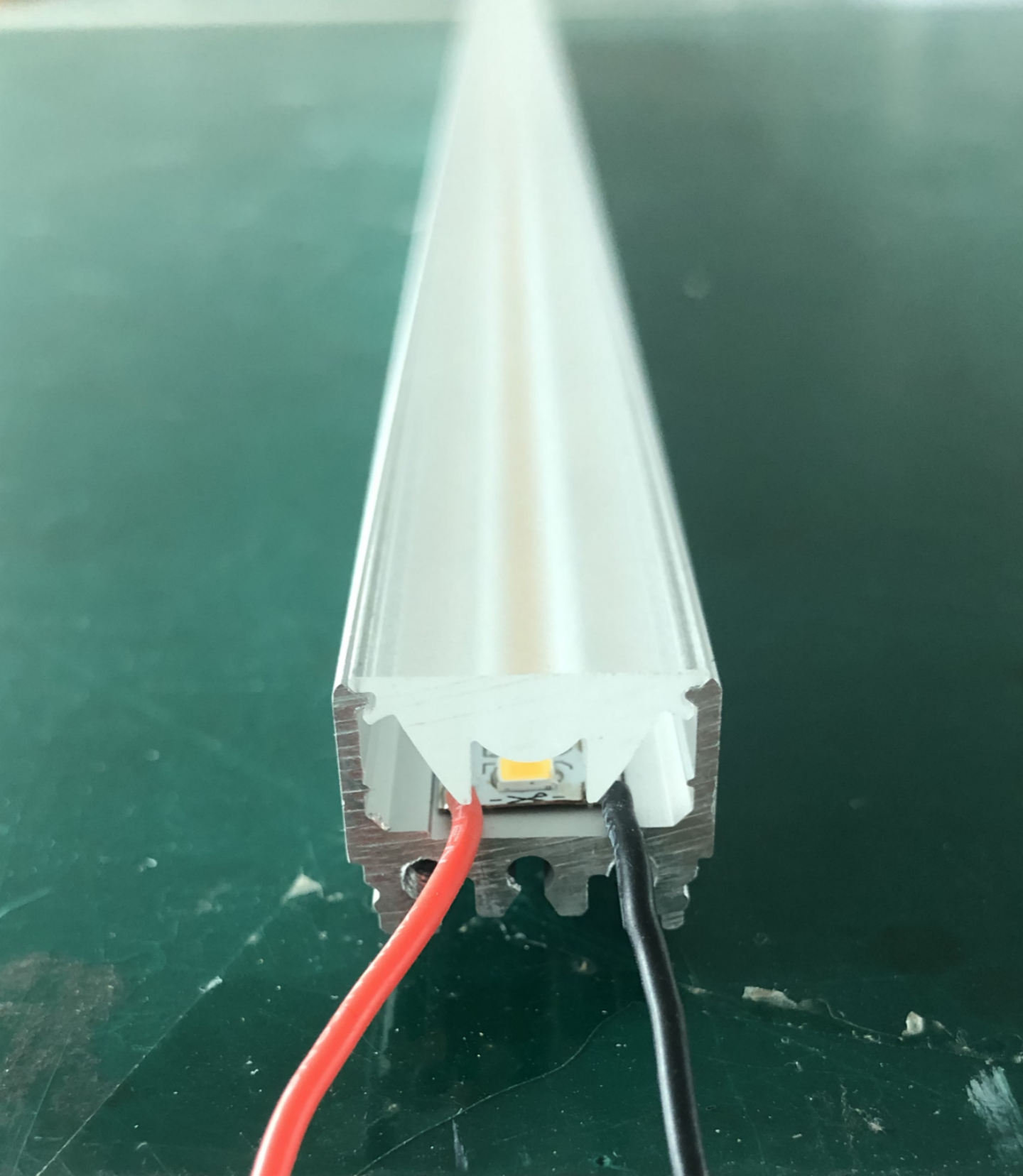

4. Structure & Assembly Test

Scan the test mold parts, compare with the drawings, ensure the structure is consistent with the drawings. And do assembly and light-up test

5. Optical Test

Test beam angle for optical lens products

6. Light Transmittance Test

Test light transmittance and haze for diffuser products

7. Provide Sample & Get Approved

Delivery samples for checking and continue to improve until approved

简体中文

简体中文