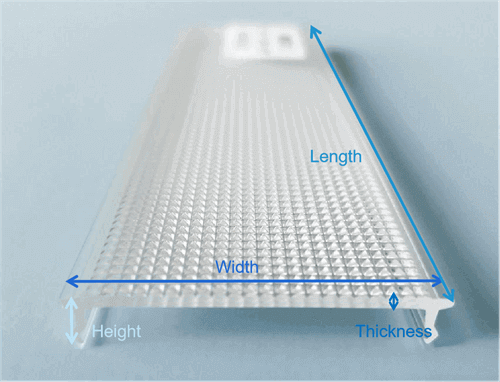

Thermoplastics Extruded Profiles Tolerance Guidelines

During the manufacture of extruded profiles, dimensions, properties or conditions may vary within certain practical limits without significantly affecting the functionality of the equipment or process. Tolerances are specified to allow a reasonable range for imperfections and inherent variability without affecting performance. The following limit values apply according to DIN 16941-2A and 2B, unless otherwise stated in the drawing and negotiate with us.

| DIN 16941-2A and 2B Standard of the Width Dimension | Special Tolerances Negotiated with Alpha | ||

| Nominal Range | Tolerance Range | Nominal Range | Tolerance Range |

| 0 - 3 mm | ± 0.3 mm | 0 - 3 mm | ± 0.1 mm |

| > 3 - 6 mm | ± 0.4 mm | > 3 - 6 mm | ± 0.15 mm |

| > 6 - 10 mm | ± 0.5 mm | > 6 - 10 mm | ± 0.15 mm |

| > 10 - 18 mm | ± 0.6 mm | > 10 - 18 mm | ± 0.20 mm |

| > 18 - 30 mm | ± 0.7 mm | > 18 - 30 mm | ± 0.20 mm |

| > 30 - 50 mm | ± 0.8 mm | > 30 - 50 mm | ± 0.30 mm |

| > 50 - 80 mm | ± 1.0 mm | > 50 - 80 mm | ± 0.40 mm |

| > 80 - 120 mm | ± 1.2 mm | > 80 - 120 mm | ± 0.60 mm |

| > 120 - 180 mm | ± 1.4 mm | > 120 - 180 mm | ± 0.70 mm |

| > 180 - 250 mm | ± 1.7 mm | > 180 - 250 mm | ± 0.80 mm |

| > 250 - 320 mm | ± 2.0 mm | > 250 - 320 mm | ± 1.0 mm |

| > 320 mm | ± 0.8 % | > 320 mm | ± 0.4 % |

DIN 16941-2A and 2B Standard of the Thickness Dimension | |||

| Nominal Range | Tolerance Range | ||

| < 1.2 mm | ± 0.2 mm | ||

| > 1.2 - 2.5 mm | ± 0.3 mm | ||

| > 2.5 – 4.0 mm | ± 0.4 mm | ||

| > 4.0 – 6.5 mm | ± 0.5 mm | ||

| > 6.5 - 10 mm | ± 0.6 mm | ||

| > 10 mm | ± 8 % | ||

DIN 16941-2A and 2B Standard of the Height Dimension | |||

| Nominal Range | Tolerance Range | ||

| 1 - 6 mm | ± 0.3 mm | ||

| > 6 - 10 mm | ± 0.4 mm | ||

| > 10 - 18 mm | ± 0.6 mm | ||

| > 18 - 30 mm | ± 0.8 mm | ||

| > 30 - 50 mm | ± 1.0 mm | ||

| > 50 - 80 mm | ± 1.4 mm | ||

| > 80 - 120 mm | ± 1.8 mm | ||

| > 120 – 180 mm | ± 2.5 mm | ||

| Alpha Standard Tolerance of the Length Dimension | Special Length Tolerances Negotiated with Alpha (which are only possible through manual rework) | ||

| Nominal Range | Tolerance Range | Nominal Range | Tolerance Range |

| 10 - 100 mm | ± 0.5 mm | 20 - 500 mm | ± 0.5 mm |

| > 100 - 200 mm | ± 0.8 mm | > 500 - 1000 mm | ± 1.0 mm |

| > 200 - 500 mm | ± 1.0 mm | > 1000 - 1500 mm | ± 2.0 mm |

| > 500 - 1000 mm | ± 2.5 mm | ||

| > 1000 - 2500 mm | ± 5.0 mm | ||

| > 2500 - 5000 mm | ± 8.0 mm | ||

| > 5000 mm | ± 0.3 % | ||

Noted:

1. Please know that tolerances are related to the material used, the shape of the profile and the application and can deviate from the listed values.

2. Special tolerances are only available for some dimensions of profile cross-sections.

3. Tolerances are guide values, which is part of our general delivery and payment terms.

Product Care

Ⅰ. Storage

Storing in open spaces is not recommended as weather-related influences may affect or damage plastic profiles. It is recommended to store plastic products on a flat base with an ambient temperature of 20°C and an average humidity of about 50%.

Ⅱ. Protection

Usually, a protective film will be put on the profile surface to protect the material from contamination and scratches. Please know that this film must be removed within six months after delivery and the plastic parts must be protected from direct sunlight, as the adhesive film may change due to temperatures exceeding 40°C and UV radiation may occur. As a result, glue residues form on the surface of plastic parts.

Also, the protective film must also be removed before a possible vacuum forming process. When the protective film is peeled off, an electrostatic charge can occur that attracts dust and dirt particles. Possibly an antistatic treatment is necessary(e. g. with ionized compressed air) before further processing.

Ⅲ. Cleaning

Water is sufficient to clean PMMA and PC. In the case of heavier soiling, products have to be cleaned with slightly warm water and mild soap. Use a clean soft cloth and press gently. Rinse with clean water and dry with a damp cloth. Dry or gritty cloths may cause scratches and electric charges on the surface.

DO NOT USE:

Window cleaning sprays, kitchen washing compounds or solvents such as acetone, gasoline, alcohol, oils, carbon tetrachloride or paint thinner or any substance incompatible with this plastic materials. These can scratch the surface and/or weaken the products, causing cracks and crazes.

简体中文

简体中文