Plastic extrusion profile tooling is an essential process in the manufacturing industry. It involves designing, fabricating, testing, and fine-tuning the tooling required to produce high-quality extruded profiles. This process requires precision and attention to detail to ensure optimal performance and longevity. In this article, we will take a closer look at the plastic extrusion profile tooling process, from design to delivery.

What is Plastic Extrusion Profile Tooling Process?

The plastic extrusion profile tooling process is the process of creating the tooling required to produce extruded profiles. Tooling refers to the parts and components required to shape and mold the plastic material into the desired profile shape. The tooling process consists of designing, fabricating, testing, and fine-tuning the tooling to ensure high-quality extruded profiles.

Designing Plastic Extrusion Profile Tooling

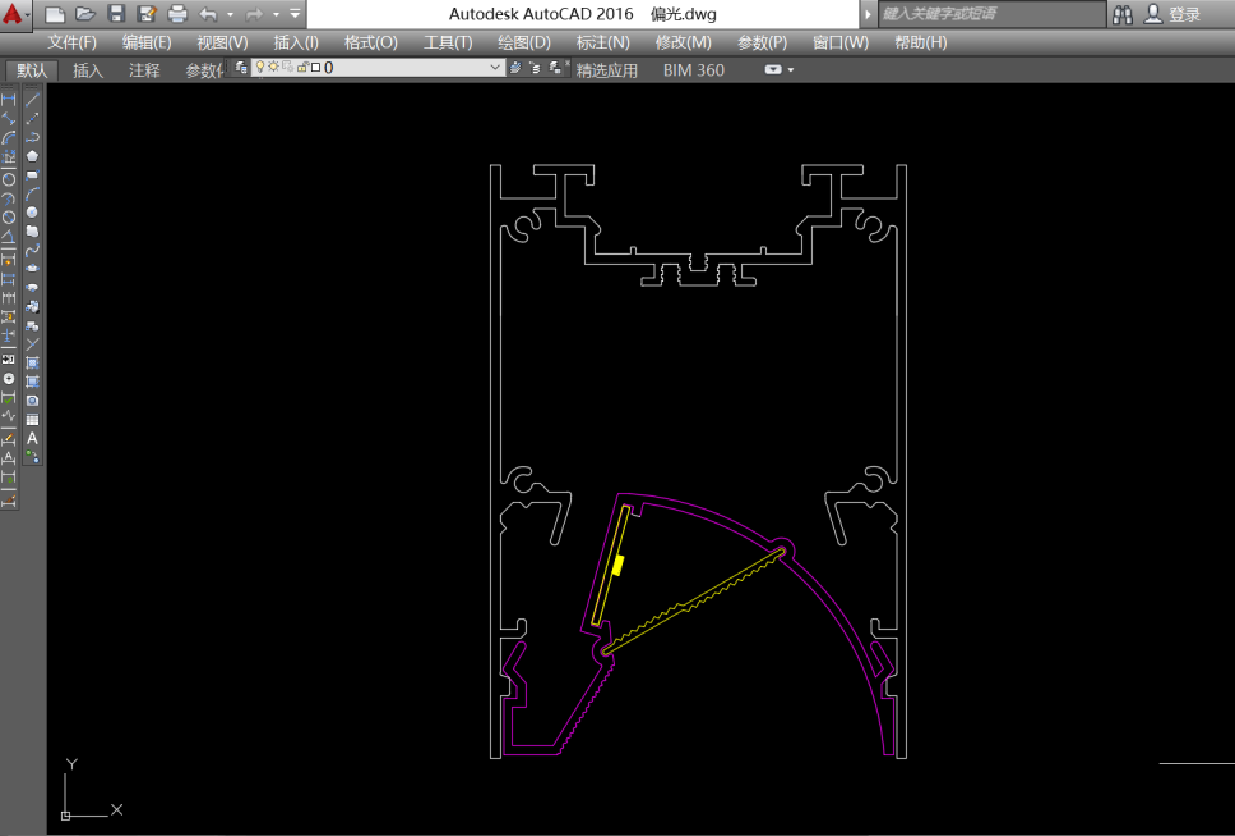

The plastic extrusion profile tooling designing phase is the initial stage of the tooling process, which involves creating a blueprint or 3D model of the tooling required to produce extruded profiles. The designing phase is a critical step that sets the foundation for the rest of the tooling process. During this phase, engineers and designers work together to create a tooling design that meets the manufacturer's specific needs and requirements.

The designing phase considers various factors, such as the material being extruded, the desired profile shape, and the dimensions of the final product. The design also considers the different types of profiles that require different tool designs, such as hollow profiles, solid profiles, or profiles with complex shapes.

The designing phase may involve the use of computer-aided design (CAD) software to create a 3D model of the tooling. The CAD software allows designers to create detailed designs and make modifications as needed. The software also enables designers to simulate the extrusion process and predict potential issues that may arise during production.

Once the tooling design is complete, it undergoes a review process to ensure that it meets the manufacturer's specific needs and requirements. During the review process, the tooling design is evaluated for accuracy, consistency, and functionality. Any necessary modifications are made before the fabrication process begins.

In conclusion, the designing phase of plastic extrusion profile tooling is a crucial step that sets the foundation for the rest of the tooling process. It involves creating a blueprint or 3D model of the tooling required to produce extruded profiles. The designing phase considers various factors, such as the material being extruded, the desired profile shape, and the dimensions of the final product. By partnering with an experienced tooling manufacturer, manufacturers can ensure that they receive high-quality tooling that meets their specific needs and requirements.

Fabricating Plastic Extrusion Profile Tooling

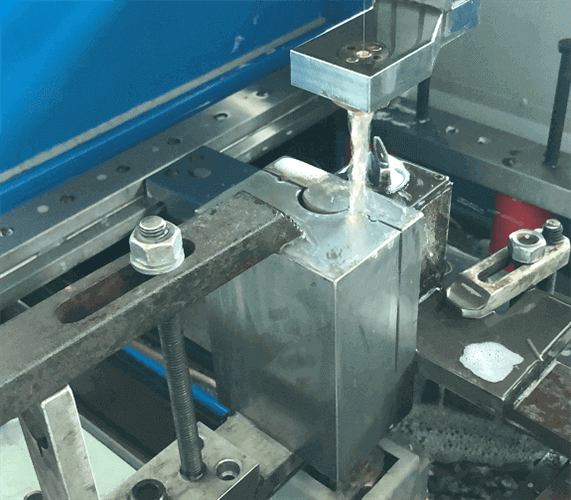

Fabricating plastic extrusion profile tooling is the process of creating the tooling required to produce extruded plastic profiles. The fabrication process involves using various materials, such as metals, to create the parts and components needed to shape and mold the plastic material into the desired profile shape.

The fabrication process starts with a design, which can be a blueprint or a 3D model of the tooling. The design considers various factors, such as the material being extruded, the desired profile shape, and the dimensions of the final product. Once the design is complete, the fabrication process begins.

The fabrication process requires precision and attention to detail to ensure the tooling's accuracy and consistency. The materials used for tooling fabrication depend on the type of profile being extruded, the desired precision, and the durability required. The fabrication process may involve various processes such as cutting, drilling, welding, and machining to create the tooling components.

Overall, fabricating plastic extrusion profile tooling is an important step in the manufacturing process that requires expertise and attention to detail to ensure optimal performance and longevity of the tooling.

Testing and Fine-Tuning Plastic Extrusion Profile Tooling

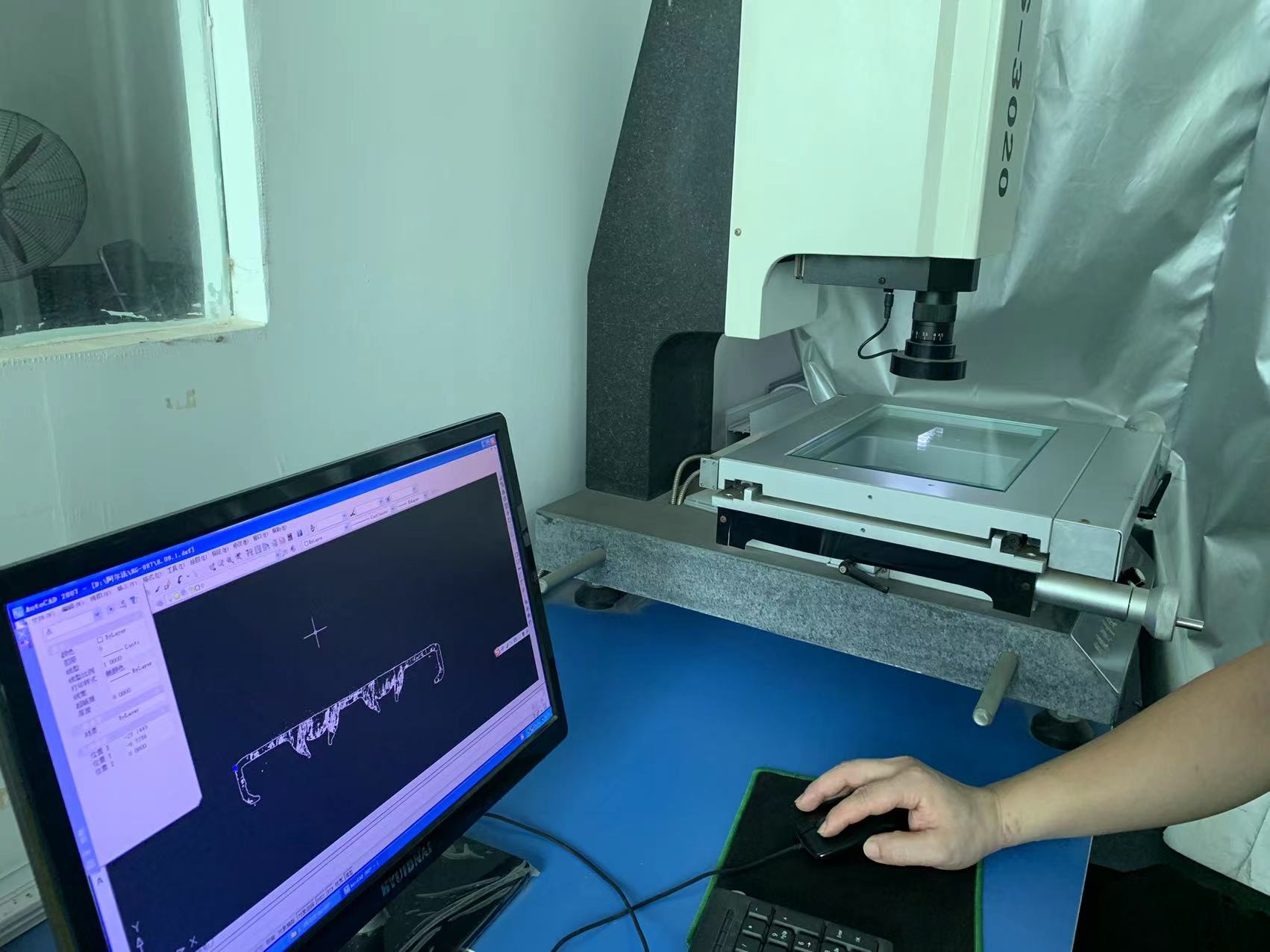

Testing and fine-tuning plastic extrusion profile tooling is a critical part of the manufacturing process that ensures the extruded profiles meet the desired specifications and quality standards. The testing process involves running a sample extrusion to ensure that the tooling produces the desired profile shape and dimensions. If there are any issues or defects, the tooling is fine-tuned to ensure optimal performance.

During the testing process, the extrusion parameters such as the speed, temperature, and pressure are carefully monitored to ensure they are within the required range for the specific material being extruded. The extruded profiles are also visually inspected for any defects, such as warping or bending, which can be an indication of issues with the tooling.

After the initial testing, any issues identified are addressed through fine-tuning the tooling. This may involve adjusting the tooling components or making modifications to the design to ensure optimal performance. The tooling is then tested again to confirm that the modifications have resolved the issues.

The testing and fine-tuning process is critical for ensuring the extruded profiles meet the desired specifications and quality standards. It ensures that the tooling is optimized for performance and durability, which is essential for the efficient and effective production of extruded profiles.

Overall, testing and fine-tuning plastic extrusion profile tooling is an essential step in the manufacturing process that helps to identify and address any issues or defects, ensuring the final product meets the required standards and specifications.

Delivery and Installation of Plastic Extrusion Profile Tooling

Once the tooling is complete, it is delivered and installed at the manufacturer's facility. Proper installation is critical to ensure optimal performance and longevity of the tooling. The installation process includes setting up the extrusion line and ensuring that all components are aligned correctly. Regular maintenance and cleaning of the tooling are also essential to ensure that it remains in optimal condition.

Conclusion

In conclusion, the plastic extrusion profile tooling process is an essential process in the manufacturing industry. It involves designing, fabricating, testing, and fine-tuning the tooling required to produce high-quality extruded profiles. The tooling process requires precision and attention to detail to ensure optimal performance and longevity. By partnering with a reliable tooling manufacturer, manufacturers can ensure that they receive high-quality tooling that meets their specific needs. Understanding the plastic extrusion profile tooling process is critical for manufacturers to ensure optimal production and profitability.

Thank you for reading our blog post on understanding the plastic extrusion profile tooling process. As a plastic extrusion profile manufacturer focus on PMMA, PC and PVC material, we are committed to providing high-quality extruded profiles to our clients. We have our own mold room where we can help you design and fabricate the tooling required to produce your desired profiles. With our expertise and attention to detail, you can be assured that the tooling will meet your specific needs and requirements.

If you're looking for a reliable partner for your plastic extrusion profile needs, we invite you to contact us. We're always ready to discuss your project and offer our expertise to help you achieve your desired outcomes. Don't settle for anything less than the best. Contact us today and experience the difference of working with a trusted plastic extrusion profile manufacturer.

简体中文

简体中文