The lighting industry has long relied on glass and transparent plastics such as PMMA(Acrylic, Plexiglass) for optical design for functional and aesthetic purposes. However, with the advent of LED lighting technology, the need for a higher degree of light diffusion has required the development of suitable plastic solutions to do a better job.

There are a variety of plastic materials, such as PC, PMMA, PS are widely used in LED lighting industry. 80% of Alpha's extruded profiles are PMMA and 20% are PC. Generally speaking, both PMMA and PC materials can replace glass, which are odorless, non-toxic, anti-bacterial and 100% recyclable. But they have different properties, do you know what's the difference between them? Let's take a look here.

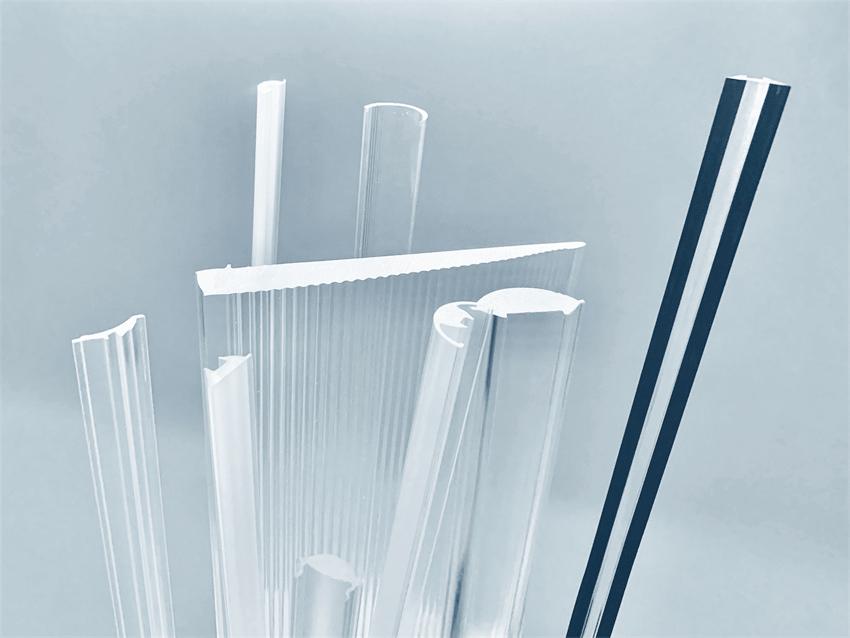

1.What is LED plastic extrusion profile?

Simply put, a Led plastic extrusion profile is the one of the housing part a Led luminaire in linear shape. There are various structures and sizes, such as flat, tube, semi-circular and irregular. Some are with beam angle which usually be called optical lens, some are not. Colors could be transparent, translucent, milky, etc. Depending on the application, some are rigid and some are flexible. They are mounted on LEDs to create the desired lighting effect. The various properties of LED extrusion lenses allow for precise control of the beam. LED plastic extrusion profiles can also provide an aesthetically pleasing appearance by concealing the LED components inside.

2. What is PMMA?

Poly-methacrylate or methacrylate (PMMA) is often referred to as Plexiglas. PMMA profile offer glass-like qualities: clarity, brightness and transparency, but at half the weight and many times the impact resistance of glass. It has an extremely shiny and smooth surface, and adapts well to products that require aesthetical characteristics.One of its qualities is high transparency, more than glass, with a coefficient of about 0.93 against 0.8-0.9 of glass.

3. What is PC?

Polycarbonate(PC) is a tough, clear plastic material with excellent strength, stiffness and impact resistance. Polycarbonate's optical clarity makes it ideal for applications such as machine guards, signs, masks, skylights and more. Polycarbonate is also widely used for architectural glazing in medical facilities, retail and government buildings, and transportation centers at risk of breakage and vandalism. In short, PC is one of the best polymers to trust in terms of durability and stability because of its high flammability class and excellent safety certificate.

4. What is the difference between PC and PMMA?

Item | PC | PMMA |

Full Name | Polycarbonate | Polymethyl Methacrylate |

Transmittance (comparison to glass) | >88% | >92% |

Flammability | PC has a lower inflammability compared to plexiglass but it is not fireproof. With some additives, it reaches some degree of self-extinguishing that varies on the basis of the thickness of the product. | PMMA is not flame retardant, burns slowly when exposed to fire and is not recommended for use in areas where fire is likely to occur. |

Aging Resistance | PC requires a special quality for outdoor use with a UV barrier and its life will be more limited. | PMMA is highly resistant to UV light and weathering. It can prolonged exposure to sunlight, will not turn yellow over time. |

Temperature Resistance | The thermal deformation temperature of PC is 135 degrees, which can withstand temperatures of up to 120 degrees in continuous use. | The thermal deformation temperature of PMMA is 90 degrees, so it is not recommended to use in temperature up to 85℃. |

Drilling | Typically PC does not crack when being drilled even if drilled close to the edge with a standard drill bit. | PMMA is easy to crack if it is drilled near an edge or with a drill bit not designed for plastic. |

Impact Resistance | 250 times of glass | 17 times of glass |

Chemical Resistance | PC has a good resistance to acids, but not to esters and ketones (ex. acetone), while it opacifies with alcohols. | PMMA has a good chemical resistance to acids, detergents, cleaning products, but is not resistant to alcohols and solvents. |

Scratch Resistance | Although PC has high impact resistance, it has very low scratch resistance. | PMMA is not easily scratched. |

Polished | PC cannot be polished. | The edges of PMMA can be polished smooth if necessary. |

Regarding costs, historically, PC was much more expensive, but today the prices are very similar, so the user must choose for its properties and suitability for its application.

5. How to identify? 3 ways to identify PMMA and PC

PMMA and PC are very similar plastics. Currently on the market, some led linear light suppliers using PC diffuser as PMMA diffuser, but PMMA diffuser is with higher light transmission, more uniformity luminous, and not easily to turn yellow. These properties are absent from PC materials. So if you want to know what material your linear light diffuser is made of, you can try the following three methods.

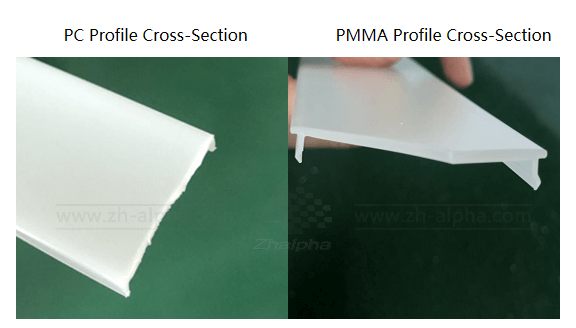

A. Observe the Cross-Section

You can use scissors or blades to try to disconnect your linear light diffuser, at this time you will find that PMMA profile is easier to disconnect than PC, as long as the side of the PMMA profile with a blade knock, there will be a gap, and then could be break off with hands. However, PC profile need to be cut with scissors. After disconnected, look at their cross-section, PMMA cross-section is more neat, PC cross-section is with a layer of white.

B. Listen to the sound

When the PMMA profile knocking on the table, the sound is crisp. And the PC sound is deeper and thicker.

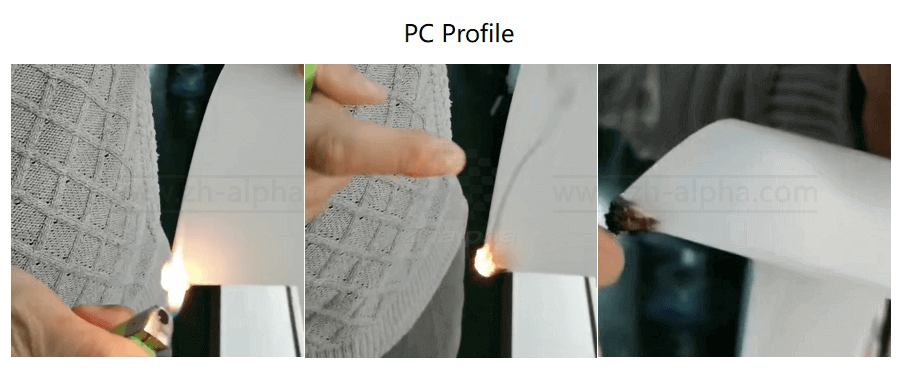

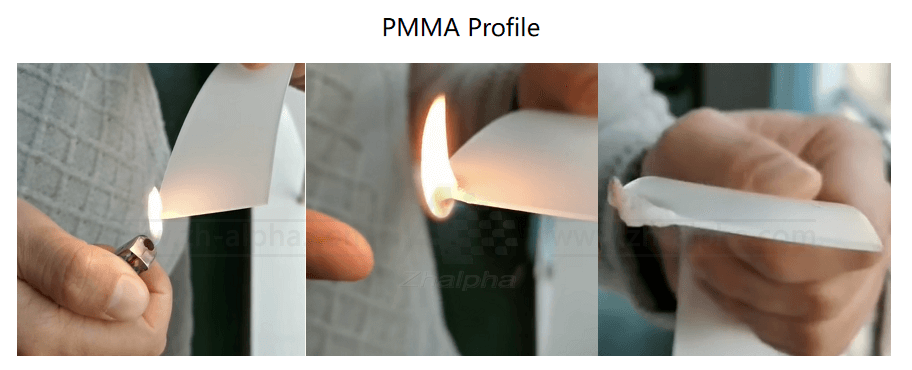

C. Ignition Test

When you burn the PC profile with fire, there will be no obvious fire because of its flame retardant property. And there is black smoke when ignited, black powder after extinguishing. PMMA profile burning flame is clear, no smoke, after extinguishing, bubble-like.

6. How to choose between PMMA and PC for light fixture?

Both PMMA and PC have unique material properties that can be used in a wide variety of applications. To find the right material for your project, it is important to take the time to compare this two plastics. This will give you a better idea of which one is best for your particular project. However, depending on your application, choosing the right plastic material should be an easy decision.

To help you choose the right material for your light fixture quickly, here are some ideal applications for each plastic:

A. Optical Lens: PMMA has the advantages of high light transmission and dimensional stability, widely used in optical lenses.

B. High bay luminaire: high bay light usually with high power, so the temperature of the luminaire will be high after long-time operation. The thermal deformation temperature of PC is 135 degrees, which suitable for use in high bay light application.

C. Transportation Lighting: usually transportation lighting projects have fire rating requirements for luminaire, requiring V0, due to the flame retardant properties of PC, usually PC light cover be used.

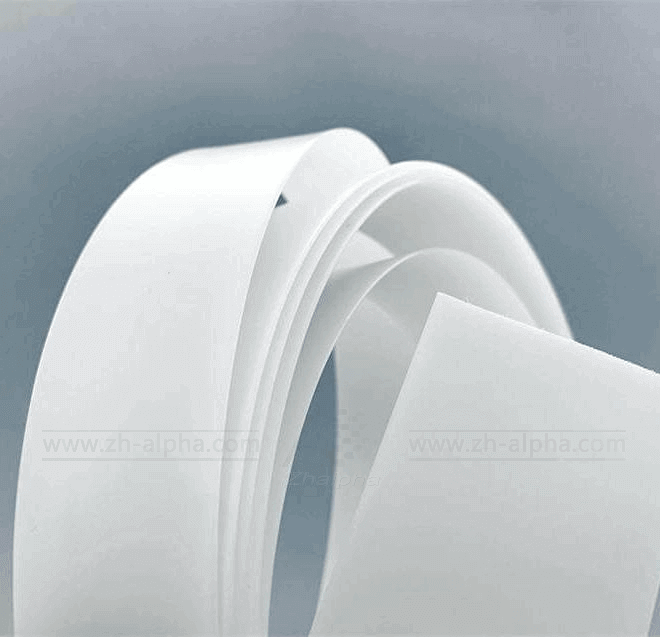

D. Led Linear light: both PMMA and PC could be used. PMMA linear light diffuser has a higher light transmission, softer light, and not easy to turn yellow over time because of its UV-resistant property. Many people' first reaction to PMMA is that this material is fragile, so they don`t want to use PMMA light diffuser for their linear light fixture, but this is a misunderstanding. Alpha focus on using PMMA material to produce extruded profiles for linear lights, it not only unbreakable, but also can be rolled up and shipped in lengths up to 50 meters per roll. Please click to have more details: Linear Light Diffuser.

For additional information concerning the most suitable raw material for your plastic profile, contact us at +86 13926996972, email: Export@zh-alpha.com

简体中文

简体中文