Everyone can say that their product is the best. We do not want to only say so but to prove you, step by step, why our products are“the best of the best”.

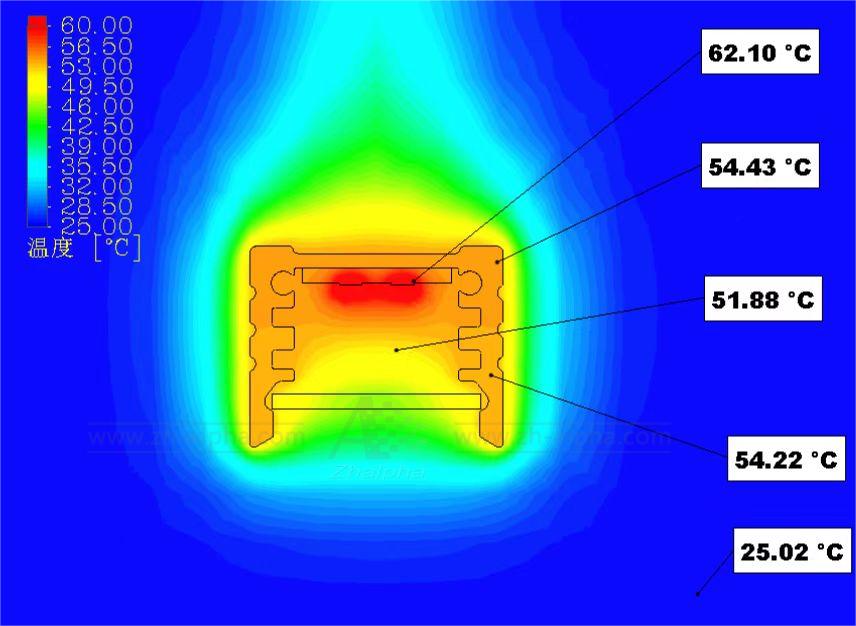

Before our designs go into production, they must pass important tests that validate the design concept in many ways. We perform detailed manufacturing analysis, such as thermal management, heat dissipation and light distribution, to ensure the product's ability to dissipate heat under certain loads and certain environmental conditions, as well as lighting performance. These analyses help us save time and money, and ensure that the physcial item meets all requirements.

You may notice many products on the market that look![]() like a "shell" rather than a real heat sink. They are not produced in enough quantities of aluminum and most of them are only mimicking the similarity in shape of the original product. The parameters between our profiles and many other similarly shaped products on the market are not comparable. When the profiles are heavier, as our products are, they perform much better: the heat is taken away much faster.

like a "shell" rather than a real heat sink. They are not produced in enough quantities of aluminum and most of them are only mimicking the similarity in shape of the original product. The parameters between our profiles and many other similarly shaped products on the market are not comparable. When the profiles are heavier, as our products are, they perform much better: the heat is taken away much faster.

The wall thickness and low aluminum weight of the profiles are driven by low cost. Due to the inability to dissipate heat in time, the LEDs are kept in a high temperature housing for a long time, which makes the life of the LED greatly reduced, and increases the possibility of frequent failures, requiring frequent replacement and repair, which usually costs several times more than purchase a efficient heat sink at the beginning. To extend the life of your LEDs, you need to use an effective heat sink, select the correct aluminum weight and thermal capacity according to you application. This is the only way to save your money and time. Don't let it happen, seek advice and analysis from our experts today and we would analyze and advise based on your project.

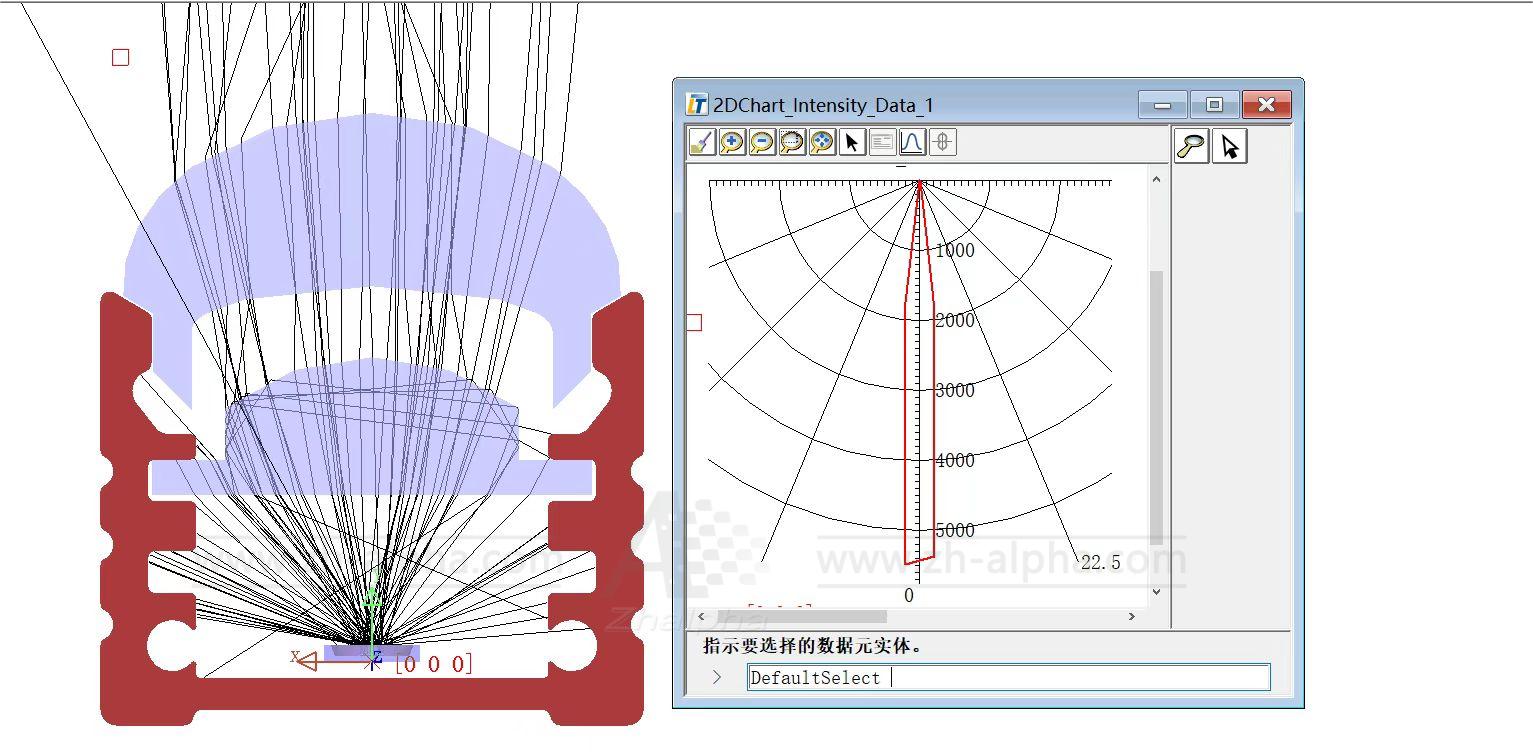

After the thermal analysis, we need to perform lighting rays analysis and efficiency optimization, especially for optical products. As you may have noticed, not many producers pay attention to this, and those who do, increase the efficiency of the luminaire by 10-15% as the end result.

The proper internal shape is optimizing to the minimum the internal light rays bouncing inside the profile. In other words, luminaires are brighter because more light is delivered to the surface and the light brings more energy because the rays haven`t bounced many times before reaching the surface. This important aspect makes a big difference and helps reduce energy and power consumption because low power LEDs can provide the same effect (luminous flux) as they normally achieve at higher power loads. Proper internal construction optimizes the internal light reflected within the profile to a minimum. Choosing the right heat sink is critical, but selecting a product with optimized light distribution helps to reduce initial power and meets the required brightness with a smaller power load. The proper light distribution helps the light to reach the surface without unwanted and unnecessary bounce. As a result we get a luminaire that is brighter and have less power consumption. All those elements are the necessary steps that we need to take into account when designing and producing LED light fixtures.

During our physical testing of each profile, we will also continuously optimize the beam blends performance, to achieve smooth beam blends, without yellow blends. We can perform lighting rays analysis based on your project requirements, using the specifications of the LED strips you plan to use, to achieve optimal results.

3. Durability of the diffuser’s color and the light efficiency

4. Anodizing process of the surface to protect against corrosion

We are using the highest standard aluminum ingot in China to produce the 6063-T6 aluminum profile, which is stronger than 6063-T5, and the deep anodizing of the profile protects the aluminum against corrosion, extends durability, and provides more scratch resistance during transportation and handling. Alpha's aluminium profiles have a premium anodised finish, which is without any extrusion marks, the texture is deep and with a very nice finish. Unfortunately, there are many cheap products on the market that have surface defects, full of scratches, and have very shallow anodized surfaces. For some buyers, these cheap products may look fine unless they compare them to a truly premium product. The fine, deep anodizing process takes time, and time is money, so it's important to understand the differences between some products and its relation to their final price. As our strategy and goal, we choose to produce the highest quality products, specifically designed to dissipate heat, cost more, but be more efficient, and be more durable.

If you are looking standard excellent aluminum profiles for your luminaire, please have a look on our wide range of products to check it out. There are 40+ standard LED aluminum models available for different applictaion, and a full set of accessories are available for your choose for all our profiles. Contact us today to have a look.

We are constantly working on new designs and new applications to expand our product range. Partnering with us will keep you ahead of the curve in the market for innovative and competitive lighting products. With our excellent service, you will have a full support and access to new products, new technologies and new ideas. Our products will establish your position among your competitors. Our products can be developed and produced under OEM conditions. We are open to your ideas and new thoughts, Alpha is always where your ideas turn into shape.

Communication with us is simple and efficient. All of our products are stocked in large quantities, so you don't have to invest in a large supply or purchase a MOQ each time. And our response time to your purchase order is immediate, usually between 1 and 3 business days starting from our warehouse to the shipping company. Contact us today to start your wonderful project!

简体中文

简体中文