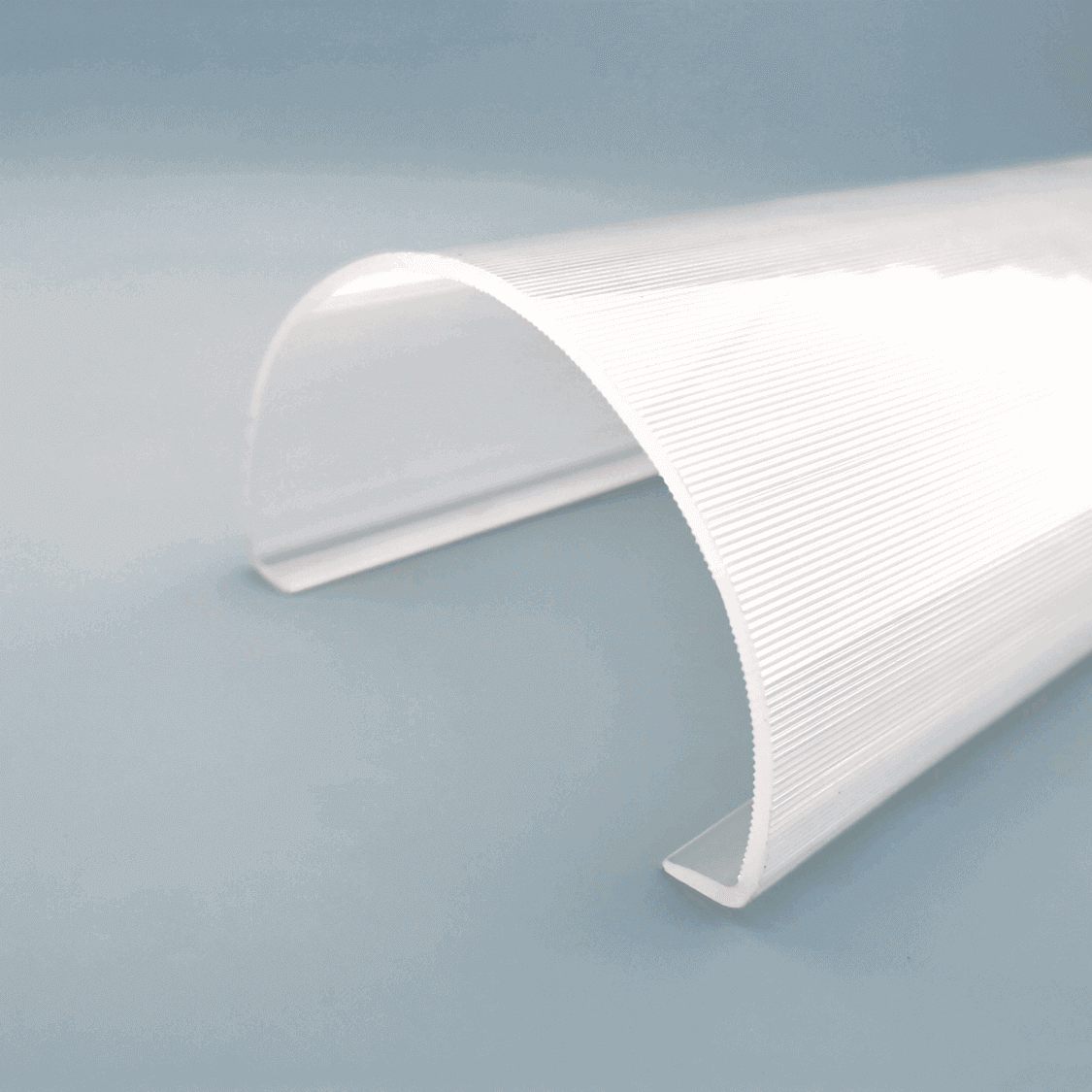

Extruded optical lenses are lenses made using extrusion manufacturing techniques, in which a material is heated and pushed through a shaped die to form a specific shape. These lenses are used to shape and direct light in a variety of applications, including in lighting fixtures, automotive lighting, and more. Extruded optical lenses come in various shapes and sizes, and can be customized to fit specific lighting needs. They are designed to optimize light output and minimize waste, making them an important tool in the field of lighting design.

Importance of understanding different types

Understanding the different types of extruded optical lenses is important because each type has its unique properties, advantages, and disadvantages. By understanding the different types, you can select the lens that best meets your specific lighting needs. Choosing the wrong type of lens can lead to poor lighting performance, inefficient use of energy, and increased costs. For example, using a Fresnel lens when a diffuser lens is needed will result in a narrow beam of light instead of an even, diffused glow. Conversely, using a diffuser lens when a Fresnel lens is needed will result in a loss of light intensity and inefficient use of energy. Understanding the different types of extruded optical lenses can help you optimize your lighting design for maximum efficiency, performance, and cost-effectiveness.

This blog post provides an overview of the various types of extruded optical lenses available for shaping and directing light in different applications. The post covers four main types of extruded optical lenses: Fresnel lenses, Total Internal Reflection (TIR) lenses, diffuser lenses and collimator lenses. Each type is explained in detail, including its properties, advantages, and typical applications, also includes tips for choosing the right type of lens, based on factors such as the light source, lighting application, and optical efficiency. Overall, this blog post aims to provide you with a comprehensive understanding of the different types of extruded optical lenses available and how to choose the best one for their specific lighting needs.

4 Different types of extruded optical lenses

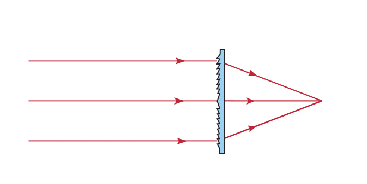

Fresnel lenses are a type of optical lens that use a series of concentric prisms on one side to bend light and focus it into a beam. These lenses were invented by French physicist Augustin-Jean Fresnel in the early 19th century and have since been widely used in various applications. The main characteristic of Fresnel lenses is their unique design, which allows them to focus light into a beam while using less material than traditional lenses. This is achieved by dividing the lens into a series of concentric rings, each with a slightly different angle of curvature. The rings act like tiny prisms, bending the light as it passes through the lens and focusing it into a beam. Fresnel lenses are commonly used in lighthouses, automotive headlights, stage lighting, and projectors.

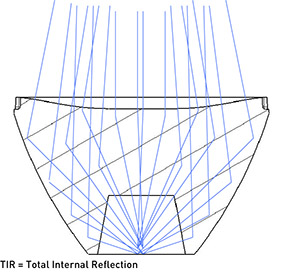

Total Internal Reflection (TIR) lenses are a type of optical lens that use the principle of total internal reflection to control the direction of light. These lenses are made of a high refractive index material, such as glass or plastic, and have a curved surface that is coated with a reflective material, such as silver or aluminum. The main characteristic of TIR lenses is their ability to reflect light at certain angles, which allows them to control the direction of light. When light enters the lens at an angle greater than the critical angle, it undergoes total internal reflection and is reflected back into the lens. By varying the curvature of the lens surface and the angle of incidence of the light, TIR lenses can be designed to collimate, focus, or diffuse light. TIR lenses are commonly used in applications where precise control of light direction is required, such as in LED lighting systems, automotive lighting, and projectors. They are also used in optical communication systems, such as fiber optics, to transmit light over long distances without losing the signal. Overall, the main characteristics of TIR lenses are their ability to control the direction of light through total internal reflection and their versatility in various applications.

Diffuser lenses are a type of optical lens that are designed to scatter and diffuse light in a specific pattern or direction. They are typically made from materials with a high refractive index, such as acrylic or polycarbonate, and have a surface that is textured or coated to scatter light. The main characteristics of diffuser lenses include their ability to soften and spread out light, reducing glare and hot spots. They can be used to create more even illumination, reduce reflections, and improve the appearance of lighting fixtures. Diffuser lenses come in various shapes and sizes, and can be designed to achieve different levels of light diffusion. Some diffuser lenses are designed to scatter light in a uniform pattern, while others are designed to create specific lighting effects, such as a gradient or a pattern. Diffuser lenses can also be used to reduce the brightness of a light source, which can be useful in applications where the light needs to be dimmed or softened. They can be used in a wide range of lighting applications, including indoor and outdoor lighting, architectural lighting, and display lighting. Overall, diffuser lenses are a useful optical component that can be used to control the direction and quality of light in a variety of applications. Their ability to scatter and diffuse light makes them an important component in many lighting systems.

Collimator lenses are designed to create a highly collimated beam of light, with minimal dispersion or spread. Collimator lenses are commonly used in applications such as laser pointers, optical communication systems, and medical equipment.

Considerations for choosing a lens type

When choosing a lens type for your lighting or optical system, there are several key considerations to keep in mind. These include:

Application requirements: The first consideration is to understand the specific requirements of your application, including the desired lighting effect, the type of light source being used, and the environmental conditions in which the system will be used.

Optics design: Depending on the application requirements, certain types of lenses may be better suited to achieve the desired lighting effect. It's important to work with an experienced lens manufacturer who can help you design the optimal optics solution for your needs.

Material selection: The choice of lens material can also impact the performance and durability of the system. Factors to consider include the refractive index, the dispersion properties, the thermal and chemical resistance, and the cost of the material.

Manufacturing process: Different types of lenses may require different manufacturing processes, such as injection molding, extrusion, or precision machining. It's important to choose a manufacturer who has the expertise and equipment needed to produce high-quality lenses using the appropriate manufacturing process.

Cost and budget: Finally, it's important to consider the cost and budget for the project. Certain types of lenses may be more expensive than others, and it's important to balance the performance and functionality requirements with the available budget.

By carefully considering these factors, and working with an experienced and reputable lens manufacturer, you can choose the right type of extruded optical lens for your lighting or optical system, and achieve the desired performance, efficiency, and functionality for your needs.

Benefits of working with a professional optical lens manufacturer

Working with a professional optical lens manufacturer can offer a range of benefits for your lighting or optical system. These benefits include:

Expertise and experience: Professional manufacturers have the knowledge, experience, and expertise needed to design and produce high-quality extruded optical lenses that are tailored to your specific needs and performance requirements. They can offer valuable insights into the design and engineering process, and help you optimize the performance and efficiency of your system.

Quality and consistency: Professional manufacturers use advanced manufacturing processes and quality control procedures to ensure that each lens is precise, reliable, and optimized for your application. They can provide consistent quality and performance, and ensure that each lens meets or exceeds your expectations.

Customization and flexibility: Professional manufacturers can offer a wide range of customization options, including material selection, lens design, and manufacturing processes. They can tailor the lens to your specific needs, and offer flexibility to adapt to changes in your application requirements.

Cost-effectiveness: Professional manufacturers can offer cost-effective solutions that balance performance and functionality with budget constraints. They can help you optimize the design and engineering process to minimize costs while still achieving the desired performance and functionality for your system.

Support and service: Professional manufacturers can offer ongoing support and service, including technical assistance, troubleshooting, and maintenance. They can help you maximize the lifespan and performance of your optical system, and ensure that it continues to meet your needs over time.

Overall, working with a professional optical lens manufacturer can help you achieve the best possible performance, reliability, and efficiency for your lighting or optical system. They can offer the expertise, knowledge, and resources needed to design, engineer, and produce high-quality extruded optical lenses that are tailored to your specific needs and performance specifications.

If you're looking to achieve the best possible performance and results for your lighting or optical system, it's important to work with a professional and experienced extruded optical lens manufacturer. A reputable manufacturer can offer the expertise, knowledge, and resources needed to design, engineer, and produce high-quality extruded optical lenses that are tailored to your specific requirements and performance specifications.

At our company, we specialize in designing and manufacturing a wide range of extruded optical lenses, including Fresnel lenses, collimator lenses, TIR lenses, and diffuser lenses. We use advanced manufacturing processes and quality control procedures to ensure that each lens is precise, reliable, and optimized for your application.

So if you're looking to achieve the best possible performance and functionality for your lighting or optical system, we invite you to contact us today. Our team of experts will be happy to work with you to understand your needs, recommend the right type of extruded optical lens for your application, and deliver a high-quality product that meets or exceeds your expectations. Contact us today to learn more about how we can help you achieve your lighting goals.

简体中文

简体中文